Intelligent Integrated Sewage Treatment Equipment

SCKJ-WSY-

The processing capacity is 2 tons/hour to 50 cubic meters/hour, which can be customized according to user needs. The production cycle is to be determined after negotiation.

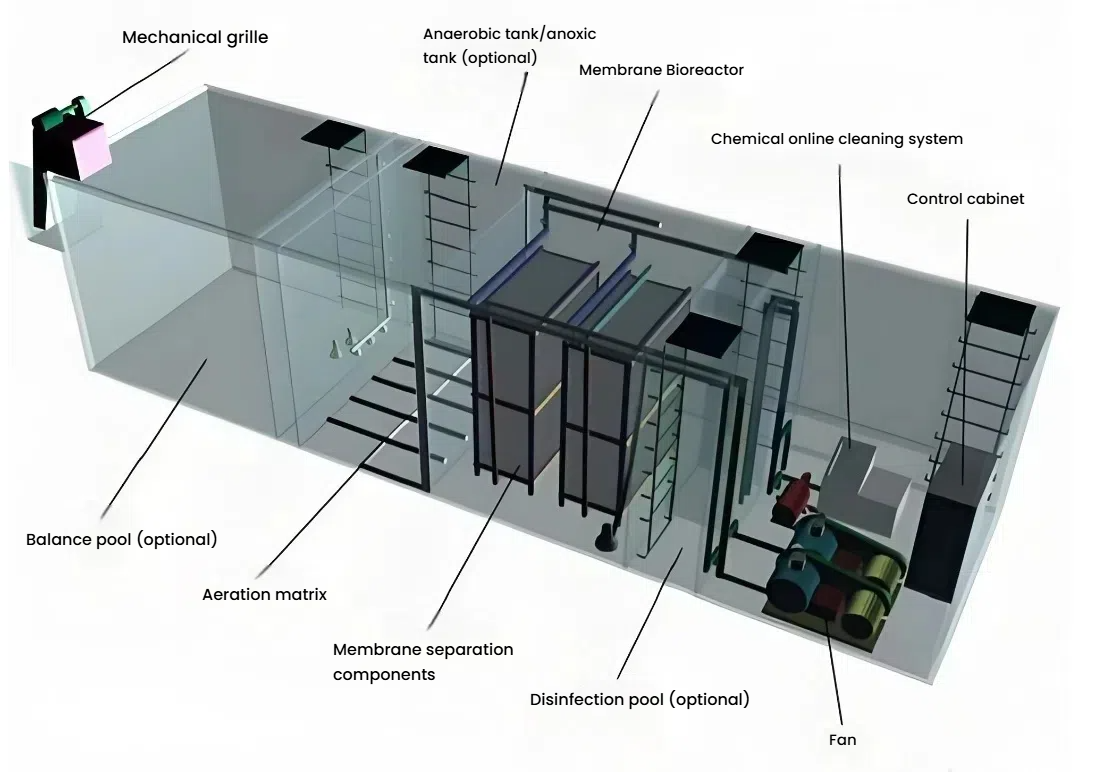

Intelligent MBR membrane integrated sewage treatment equipment is a sewage purification and treatment equipment with biological contact oxidation method + MBR membrane process as the core technology. It can be buried underground, saving the complex links of government planning approval, design and construction, insulation, etc. of ground buildings. At the same time, it has the characteristics of good effluent quality, stable operation, automatic operation, simple management, and low noise. The combined buried sewage treatment equipment has a wide range of applications. It is suitable for the treatment of domestic sewage generated by hotels, restaurants, residential areas, new rural reconstruction, office buildings, sanatoriums and other places. It is also suitable for the treatment of organic sewage such as food, papermaking, brewing, and slaughtering.