SCKJ-FST-

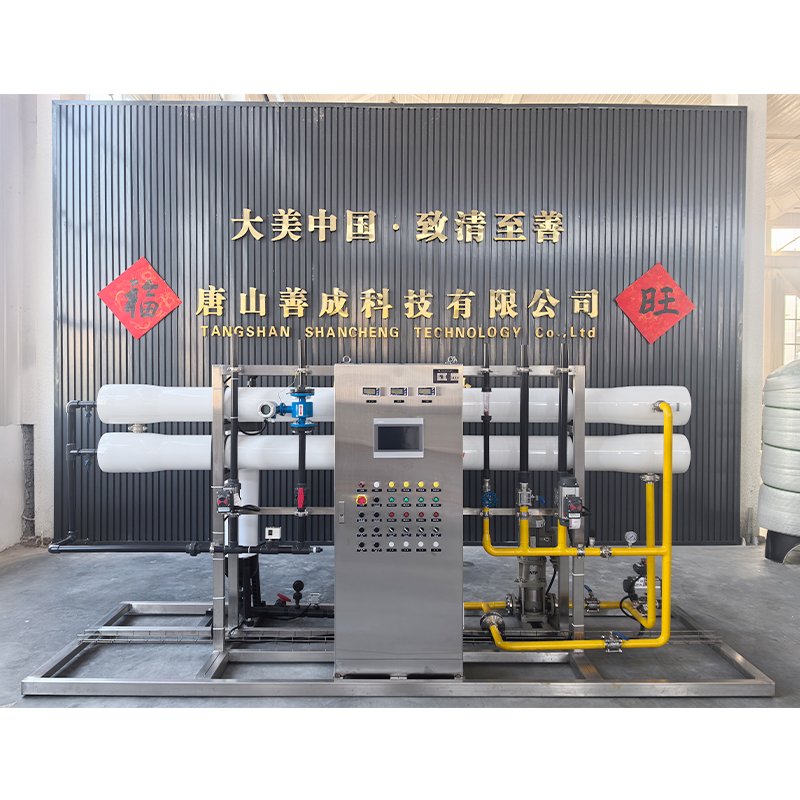

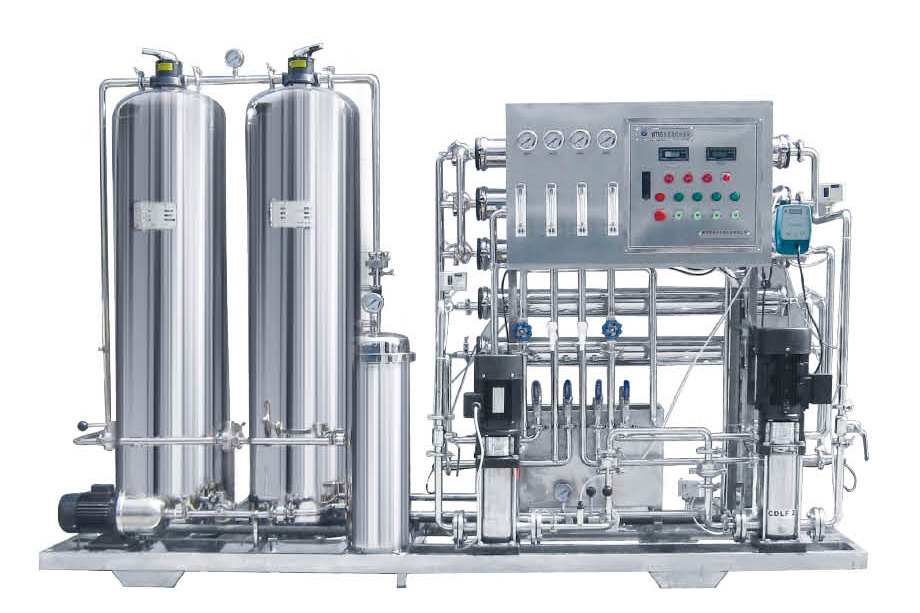

The processing capacity is 0.5 tons/hour to 1000 cubic meters/hour, which can be customized according to user needs. The production cycle is to be determined after negotiation.

Reverse osmosis equipment is to pass raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurize it through a pump, using a reverse osmosis membrane (RO membrane) with a pore size of 1/10000μm (equivalent to 1/6000 of the size of E. coli and 1/300 of the size of viruses) to turn high-concentration water into low-concentration water, while isolating all impurities such as industrial pollutants, heavy metals, bacteria, viruses, etc. that are mixed into the water in large quantities, so as to achieve the physical and chemical indicators and hygiene standards specified for drinking.

Reverse osmosis equipment uses membrane separation technology to effectively remove charged ions, inorganic substances, colloidal particles, bacteria and organic substances in water. It is a commonly used equipment in high-purity water preparation, brackish water desalination and wastewater treatment processes. It is widely used in electronics, medicine, food, textiles, chemicals, power generation and other fields.