SCKJ-GYCK-10t/d

Can be customized according to user needs. Production cycle to be determined after negotiation.

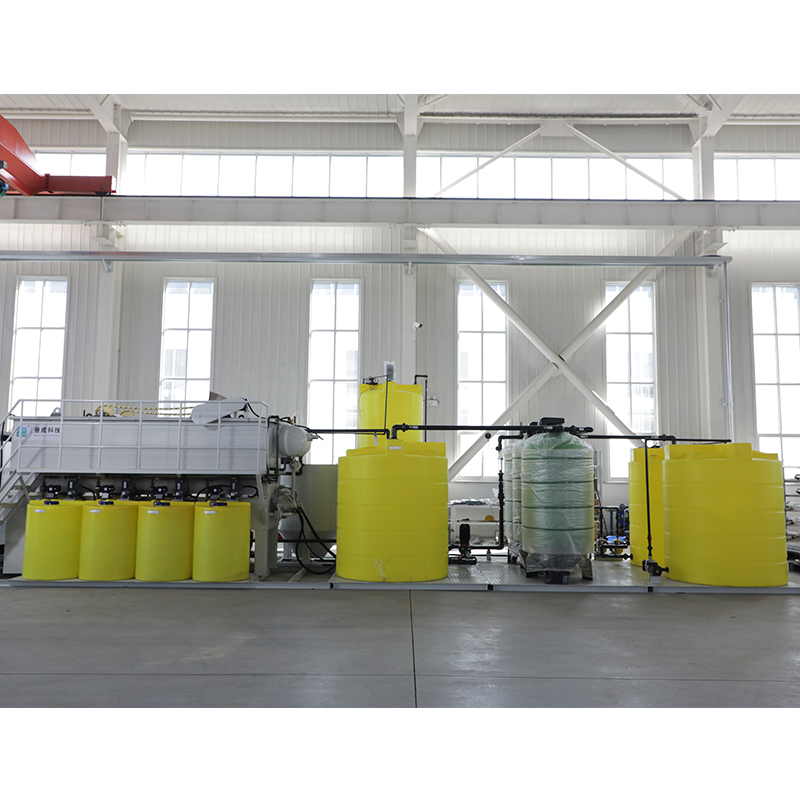

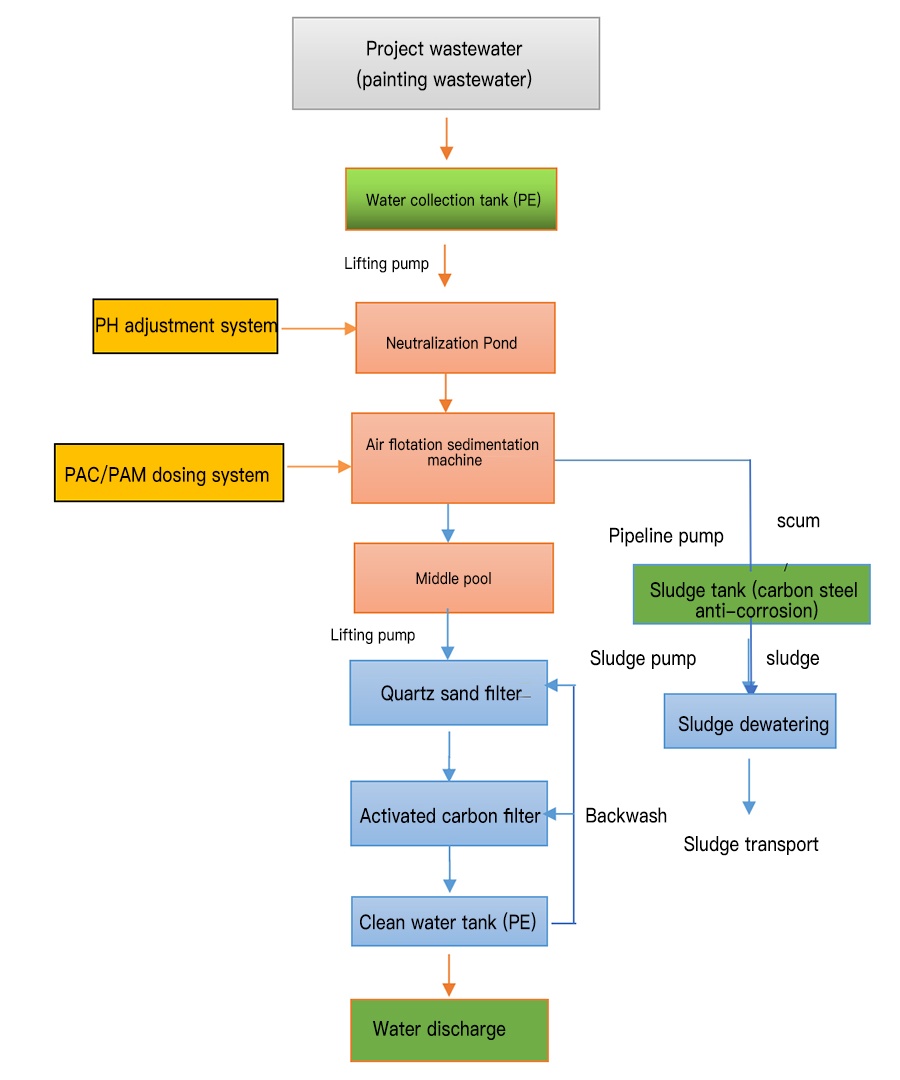

This system is a skid-mounted painting wastewater treatment system, and the production wastewater treated is mainly painting wastewater.

The system is customized according to the owner's actual production and drainage conditions, drainage volume, reserved space on site and emission standards. After the effluent meets the standards, it can be discharged into the municipal pipe network and then treated twice by the municipal sewage plant.

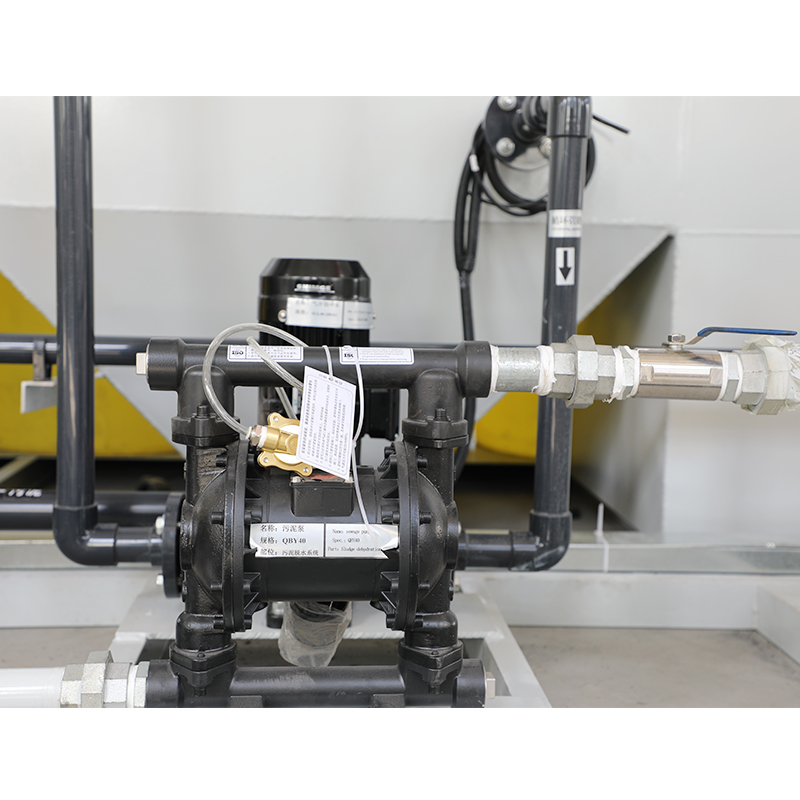

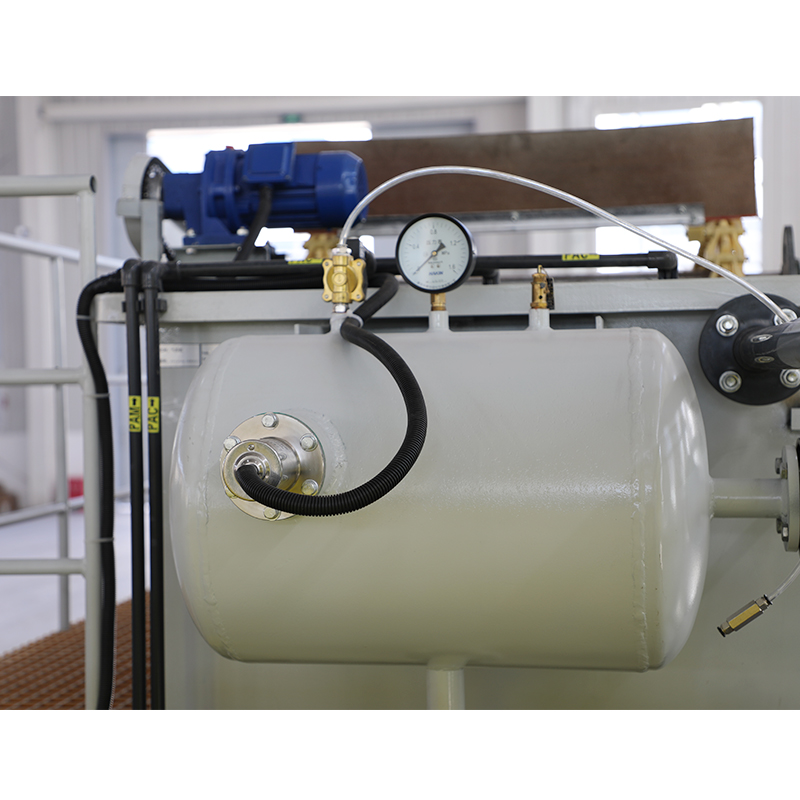

The wastewater is metal surface treatment wastewater, which mainly comes from pre-degreasing, degreasing, surface conditioning, and pre-processing processes. The wastewater mainly contains pollutants such as surfactants and emulsified oil. Spraying wastewater is generally considered cleaning wastewater, but the characteristics of wastewater are that it contains organic matter, oil, and suspended impurities. Moreover, for this wastewater, it generally contains organic components that are easily biodegradable to biological bacteria. Considering the above, this plan intends to use neutralization + high-efficiency dissolved air flotation + filtration as the main body. Metal ions, pollutants, and harmful and toxic substances in wastewater are removed through pretreatment, and the effluent meets the standards and is discharged into the municipal pipe network.